Bearing fitting tools

Mounting bearings in a cold condition

Premature bearing failure can result from damage incurred when a bearing is incorrectly mounted

Typical problems that can cause premature failures are:

Damage caused during the fitting procedure

Incorrect sized shafts and housings i.e. too loose or too tight

Retaining lock nuts coming loose in operation

Burred and damaged shaft and housing seats and shoulders

Incorrectly mounted bearings

Bearing fitting tools

Bearing fitting tool kit

Helps prevent premature bearing failures

Combi kits

Multi-purpose kits for quick and easy mounting and dismounting

Hook spanners

Exact spanner radius reduces the risk of nut damage

Hook spanner set

Most popular hook spanner sizes combined in one set

Adjustable hook spanners

Four sizes for tightening or loosening up to 24 nut sizes

Hook spanners for SNL housings

Easy and quick bearing mounting and dismounting in SNL housings

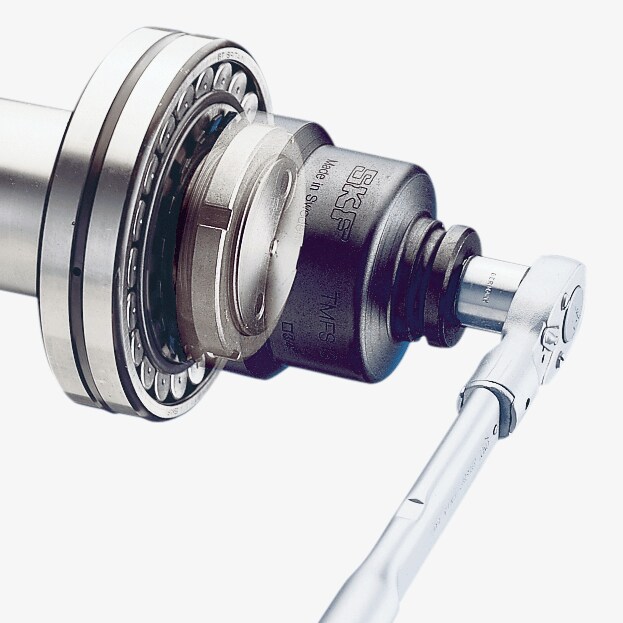

Axial lock nut sockets

Easy mounting and dismounting without nut damage

Impact spanners

High impact forces without nut damage

Lock nut spanners

For achieving the correct radial clearance

Interference fits: cylindrical shafts

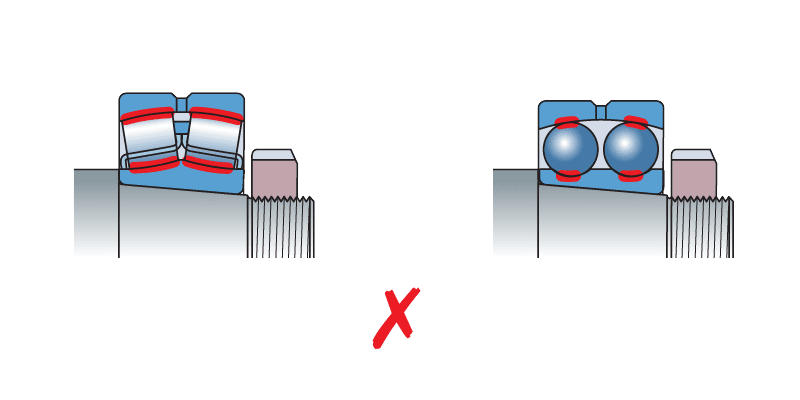

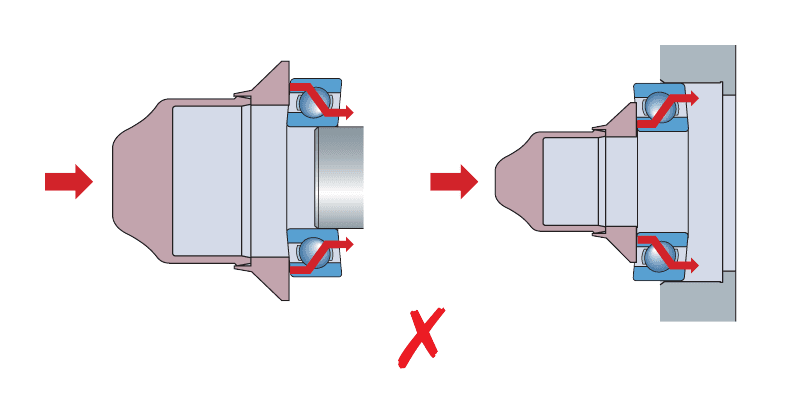

Incorrect mounting

When bearings are mounted cold, care must be taken to make sure the drive-up forces are applied to the ring with the interference fit. Damage and a resulting bearing failure can occur if the mounting force is transmitted through the rolling elements causing damage to the raceways (fig 1)

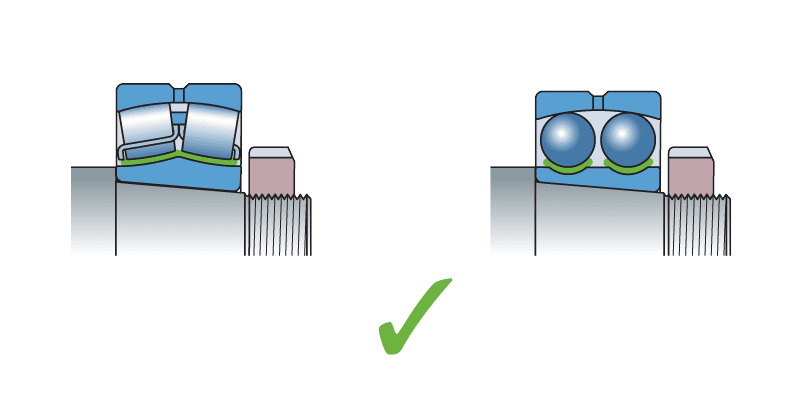

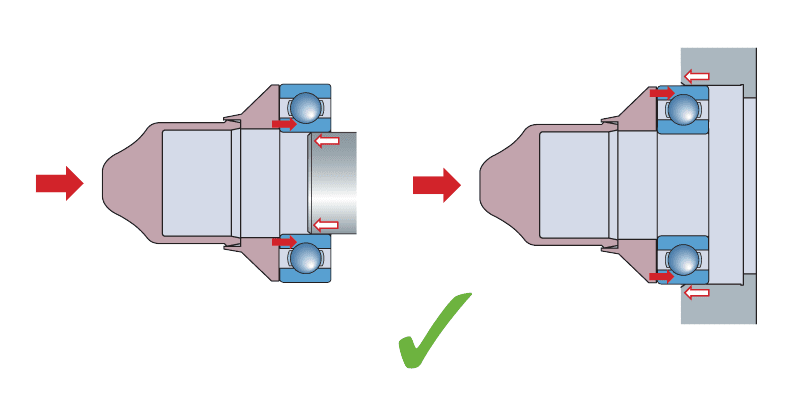

Correct mounting

The correct way to minimise raceway damage is to use specifically designed tools from SKF, such as the Bearing fitting tool kits and Combi kits. These tools allow drive-up forces to be applied effectively and evenly to the component with the interference fit avoiding raceway damage (fig 2)

Interference fits: tapered shafts

Spherical roller bearings

Method: Correct adjustment of spherical roller bearings is determined by measuring the residual internal clearance in the bearing or by the amount of axial drive-up. Details of the required reduction of clearance and axial drive-up can be obtained from tables published in the SKF General Catalogue. For larger size bearings, it is generally recommended to consider using a tapered seating to facilitate easy mounting and dismounting.

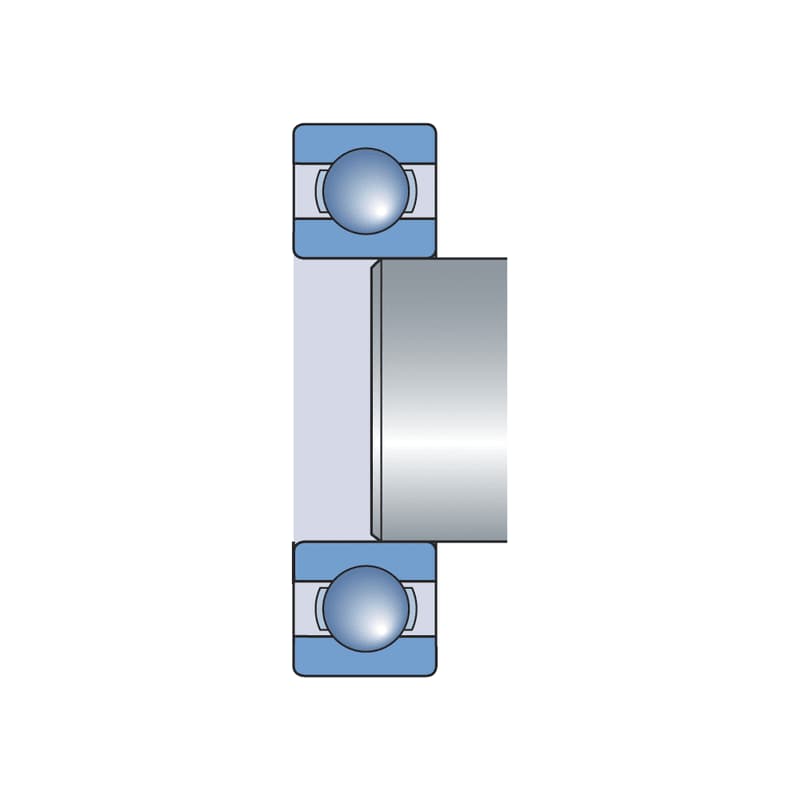

Self aligning ball bearings

Method: Adjustment of double row, self-aligning ball bearings is more difficult to achieve than spherical roller bearings because the feeler gauge method cannot be used. A very effective method to mount this type of bearing correctly is to use the SKF TMHN 7 lock nut spanner set.

Incorrectly mounted: Bearing driven up too far and all clearance removed; damage possible (fig 3)

Correctly mounted: Bearing driven up the correct distance and the right clearance is achieved (fig 4)