Heaters for mounting

Incorrect mounting methods account for 16% of premature bearing failures

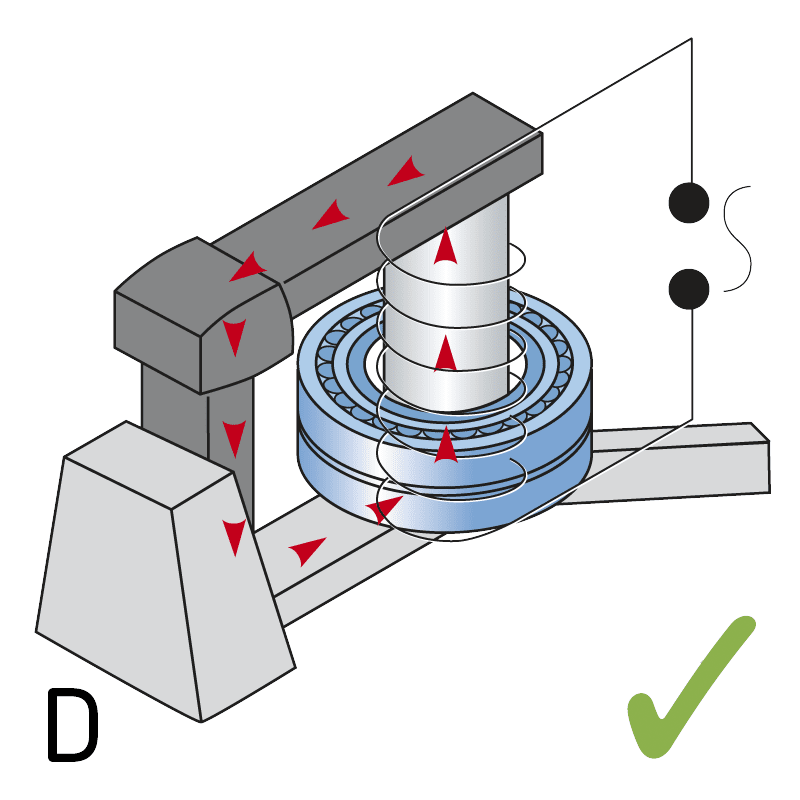

SKF Induction heaters utilise advanced power electronics with application specific designs for high performance.

As a result, by using an SKF induction heater, the total cost of ownership is often significantly lower. Ergonomics and safety are also an important consideration for operators. SKF induction heaters are equipped with design features that make them easy to use and safe. Bearing support arms reduce the risk of the bearing toppling during heating, and ergonomically designed yokes help reduce operator fatigue. In addition, the unique remote control enables the operator to control the heater at a safe distance from the hot bearing, enhancing operator safety.

Heaters for mounting

The benefits of SKF Induction Heaters

Efficiently heating bearings and work pieces, both large and small

Electric hot plate

Thermostat controlled bearing heating

Portable induction heater

A portable bearing heater weighing only 4,5 kg (10 lb)

Small induction heater

High heating capacity of up to 40 kg bearing

Medium induction heater

High heating capacity of up to 120 kg bearing

Large induction heater

High heating capacity of up to 300 kg bearing

Extra large induction heater

High efficiency,induction heater with 1 200 kg bearing heating capacity

Multi-core induction heater

A flexible heating solution for very large bearings and workpieces

Induction heaters for non-bearing applications

Specially designed to heat solid workpieces.

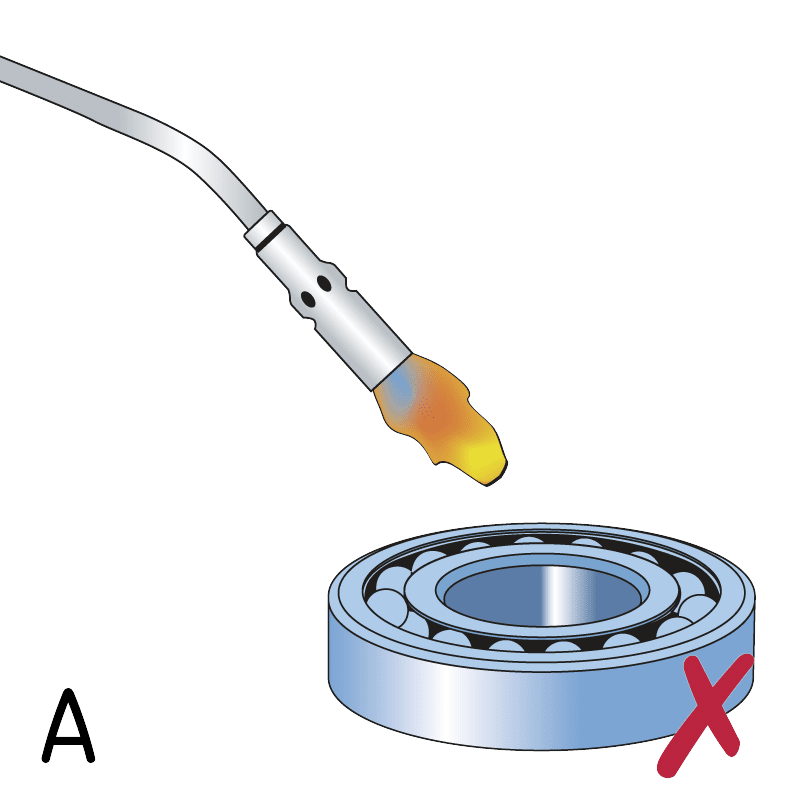

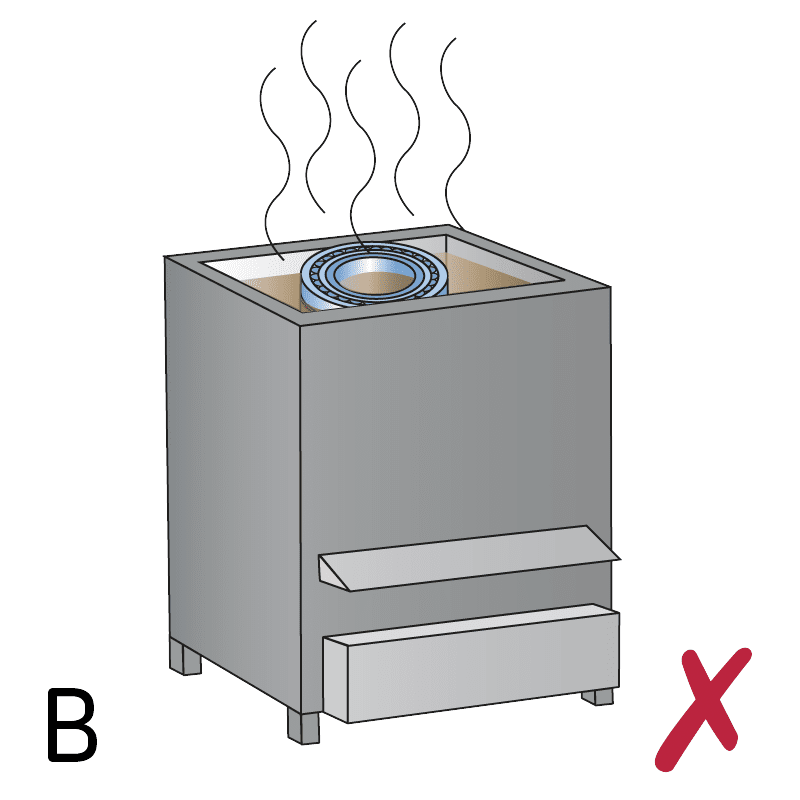

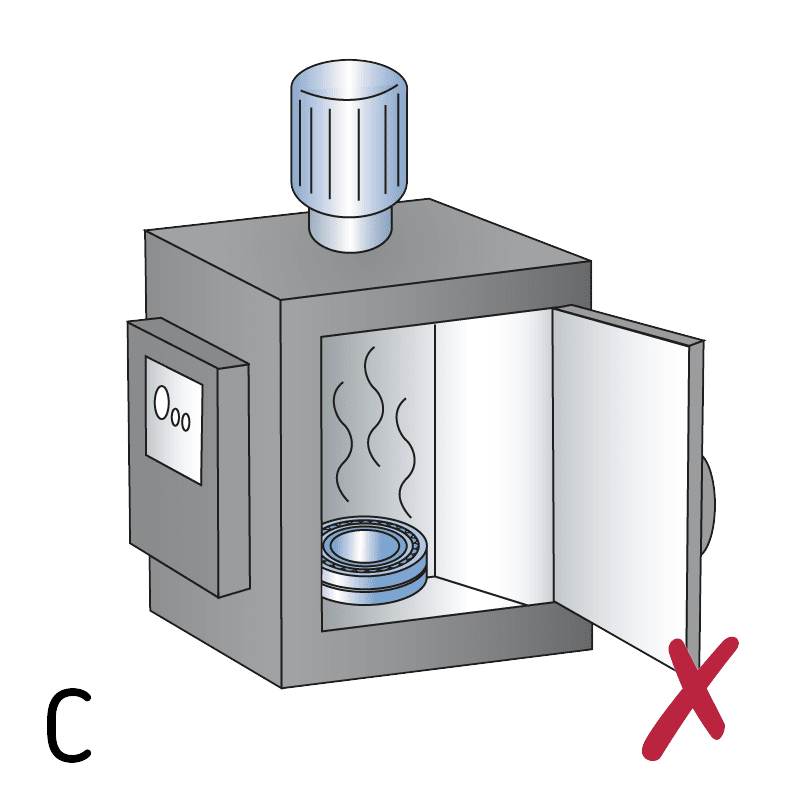

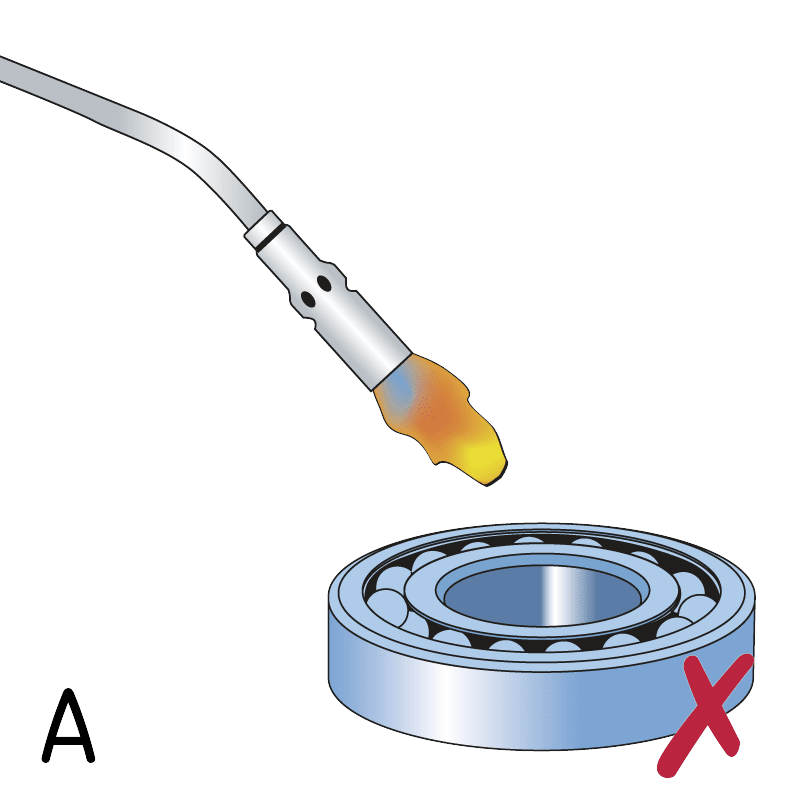

Mounting bearings using heat

Incorrect mounting methods account for 16% of premature bearing failures

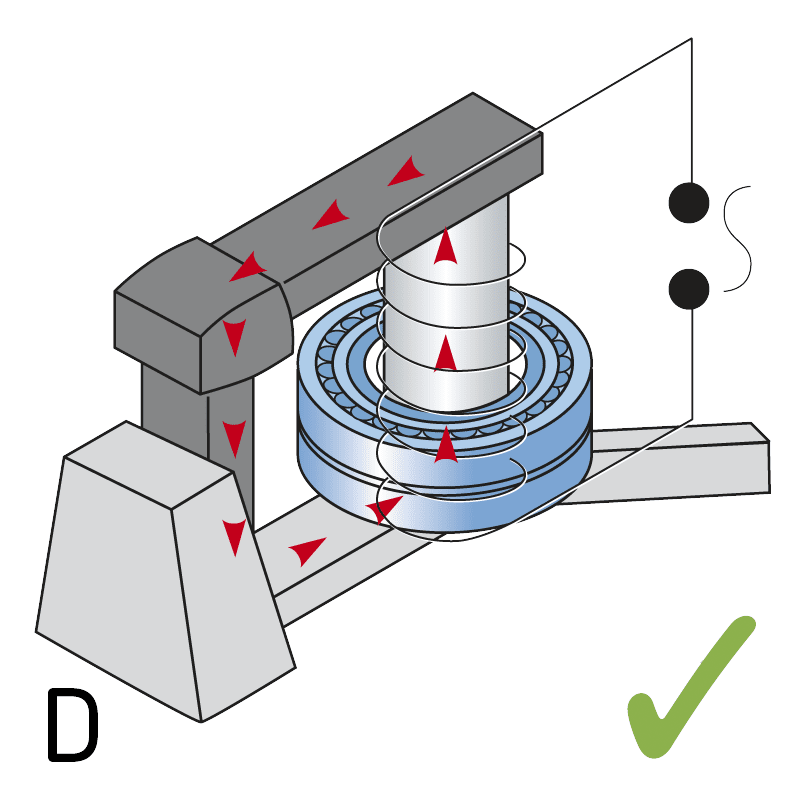

Induction heating has many advantages over other bearing heating methods