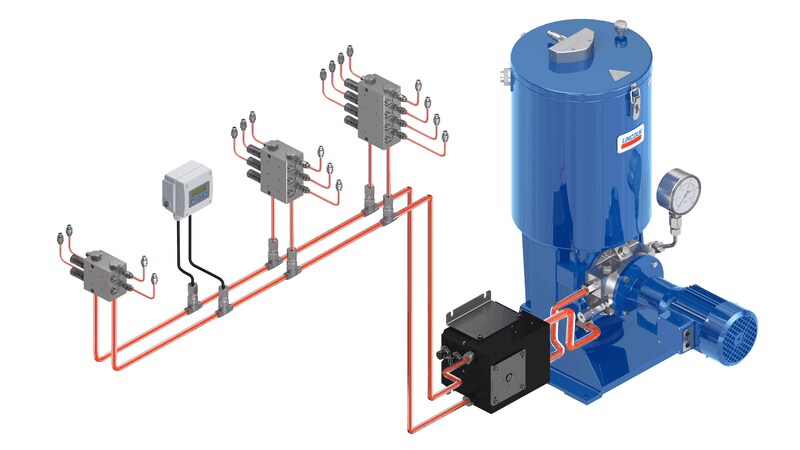

Dual-line lubrication systems

for oil, semi-fluid grease and grease up to NLGI 2

SKF and Lincoln dual-line lubrication systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5800 psi). Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points. Within large dual-line systems, end-of-line pressure switches are used to control and monitor the system.

Discover how SKF dual-line lubrication systems work

Overview of dual-line lubrication systems for grease

Benefits and applications

Flexible

simple to design, easy to extend or reduceReliable

precise, metered amount of lubricant, to up to 2000 lubrication points over long distances up to 120 mVariety of applications

heavy industry, metal working plants, pulp and paper production, mining, mineral processing, power plants, cement factories, steel works and moreEffectively in harsh conditions

including potentially high lubrication-point back pressure, dirty, wet or humid environments and low temperatures.

Pumps

Metering devices

Monitoring devices

Control units