Minimal quantity lubrication units

Using MQL eliminates the need for complicated wet machining

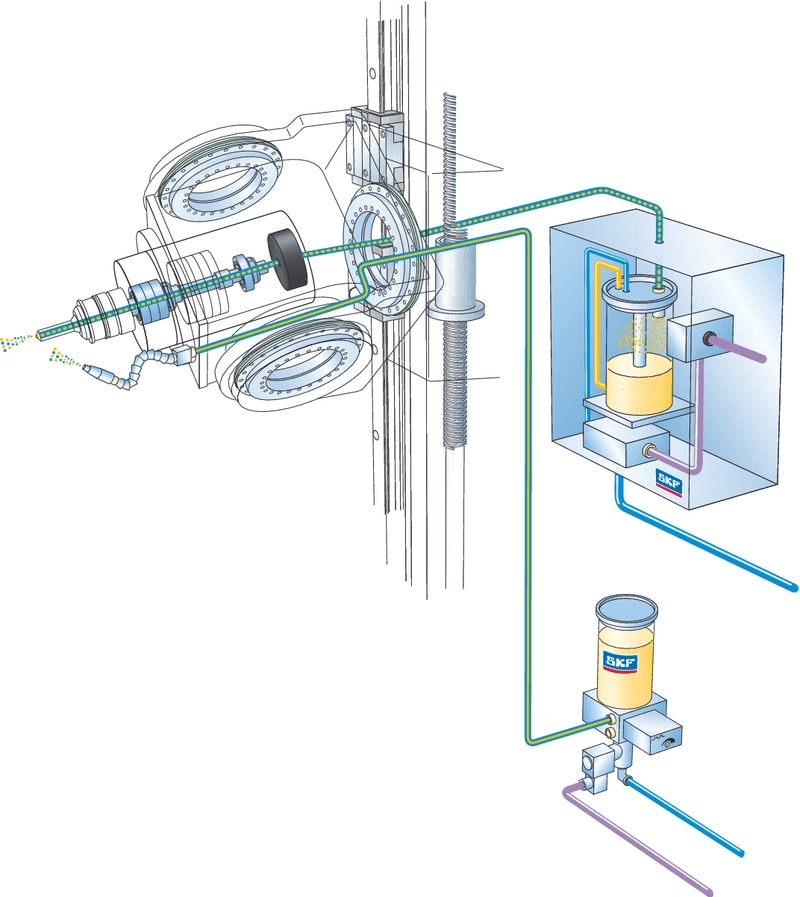

The principle is simple: The lubricant is applied to the cutting edge of the tool as an aerosol in the exact amount required. The lubrication consumption using MQL is measured in millilitres per hour instead of litres per minute.

Consistently employing SKF LubriLean instead of cooling lubricant on production lines allows for simple, efficient, and environmentally friendly factory design.

Alternating use of wet and dry machining on one machine is possible in most cases. In addition to integration in new machine tools, the low-maintenance MQL devices can in most cases also be used to retrofit existing machinery. The experience gathered using MQL technology in-house can also be integrated directly into product innovations.

There are units for external or internal MQL available. Find an overview of technical details in the table.

Discover SKF Minimal Quantity Lubrication Solutions

LubriLean Basic

LubriLean Smart

LubriLean Vario

LubriLean VarioSuper

LubriLean VarioPlus

LubriLean DigitalSuper

Vectolub VE1B

Vectolub VTEC