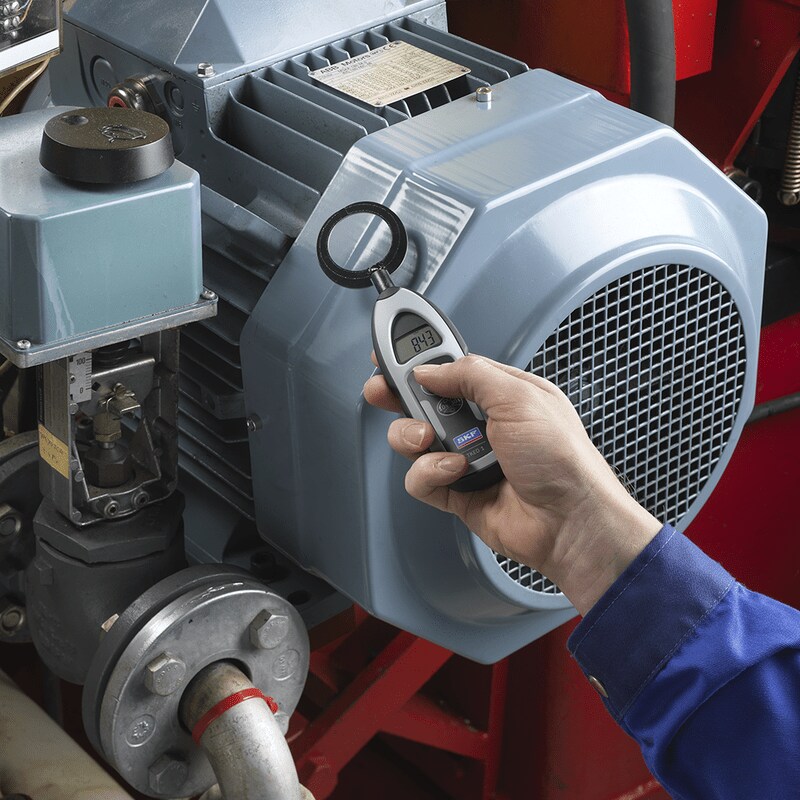

Electrical discharge detector

Detect electrical discharges in electric motor bearings

Electric motors are more vulnerable to suffer electrical erosion in bearings when controlled by a Variable Frequency Drive. When incorporated into a predictive maintenance programme, the EDD Pen can help detect bearings more susceptible to failure, and significantly prevent unplanned machine downtime.

Unique remote solution allows operation at a distance from the motors. This helps protect the user from touching machinery in motion

SKF technology*

No special training required

Capable of detecting electrical discharges on a time base of 10 seconds, 30 seconds or indefinite

LED Backlit screen, allows use in dark environments

IP 55 can be used in most industrial environments

Supplied standard with batteries, a spare antenna and language free Instructions for use in a carrying case

*Patent applied for.

SKF TKED1 (fig 1)

Supplied standard with batteries, a spare antenna and language free Instructions for use in a carrying case

Technical data

| Technical data |

|

| Designation | TKED 1 |

| Description |

SKF Electrical Discharge Detector Pen |

| Power supply |

4,5V – 3 x standard AAA batteries (LR03, AM4) |

| Time control: – pre-sets – default |

10 or 30 seconds indefinite |

| Operational and storage temperature |

0º to 50 °C (32 to 122 ºF) -20 to 70 °C (-4 to 158 ºF) |

| IP level |

IP 55 |

| Display |

LCD counter range: 0 to 99 999 discharges. User selectable backlight and low battery warning |

| Case Dimensions (l x w x h) |

260 x 85 x 180 mm (10.3 x 3.4 x 7.0 in.) |

| Total case and contents weight |

0,6 kg (1.35 lb) |

Spare parts