Basic condition monitoring products

Essential for maximum bearing service life and optimum machine performance

To help you achieve this goal, SKF has developed a wide range of instruments for analyzing the critical environmental conditions that have an impact on bearing and machine performance.

Temperature

Thermometers

Accurate temperature measurement of general equipment

Speed

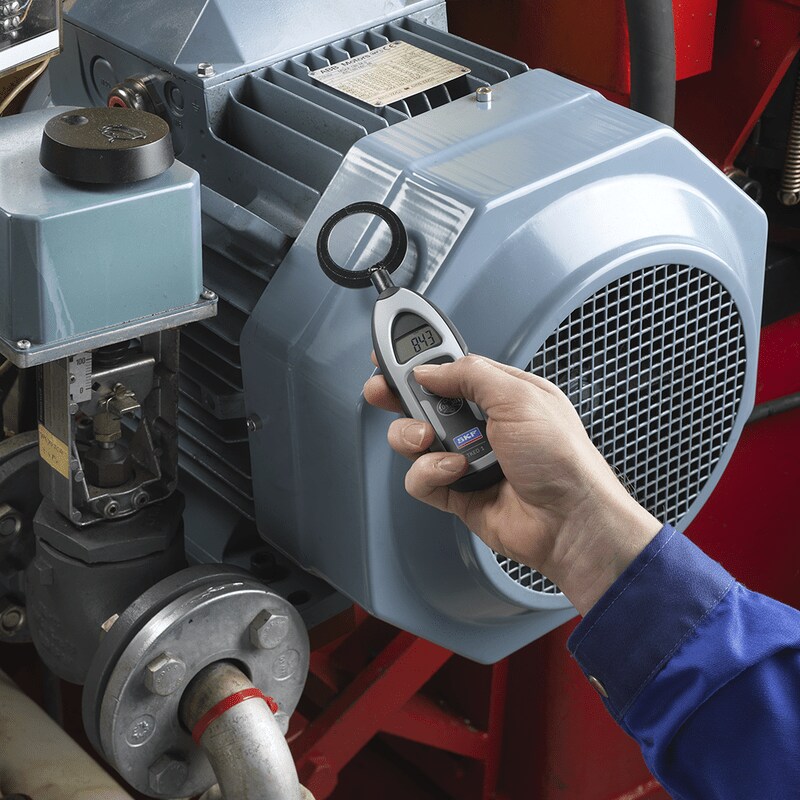

Digital tachometer

Pinpoint accuracy combined with measurement versatility

Multi-function-digital tachometer

Pinpoint accuracy combined with measurement versatility

Visual

Endoscopes

Fast and easy inspection with video function

Stroboscope TKRS 41

High performance hand-held stroboscope for machine inspections

Sound

Stethoscope

Easily pinpoints bearing and machine noise

_NG.jpg)

Sound pressure meter

Easy noise level measurement

Ultrasonic leak detector

Quick and easy detection of air leaks

Vibration

SKF Pulse sensor and app

Machine monitoring made easy

Basic handheld vibration sensor

Basic handheld vibration sensor

Static vibration sensor

Static vibration sensor

Electrical discharge currents

Electrical discharge detector

A simple to use hand-held instrument for detecting electrical discharges in electric motor bearings to prevent unplanned machine downtime