Bushings, thrust washers and strips

This page provides overviews of the available bushing, thrust washer and strip types, their designs, designations, characteristics and main application areas.

It also includes references to the relevant product sections with detailed information as well as references to the product tables.

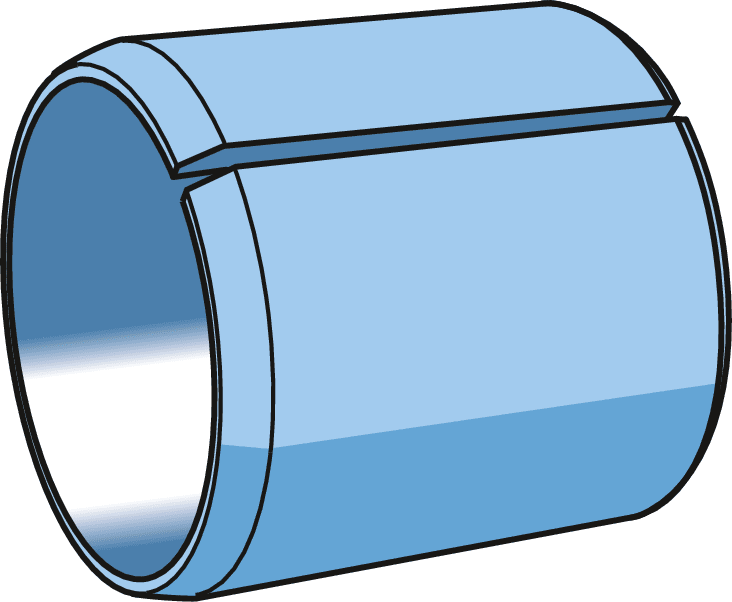

SKF solid bronze bushings (table 1) are suitable for a wide range of operating conditions and applications. The solid bronze material is particularly well suited for highly demanding applications in tough environments. SKF offers a standard assortment of both straight and flanged solid bronze bushings (fig. 1). Advantages of these bushings include:

insensitive to dirty environments

resistant to shock loads and vibrations at low speeds

possibility to operate with lower quality shaft finish

good resistance to corrosive contaminants

equipped with grooves to retain lubricant

SKF solid bronze bushings are intended for oscillating movements in both radial and axial directions. They are also suitable for applications where rotating speeds are low. Application area examples for these bushings are:

construction machinery

transport equipment

pulp and paper making machinery

offshore equipment

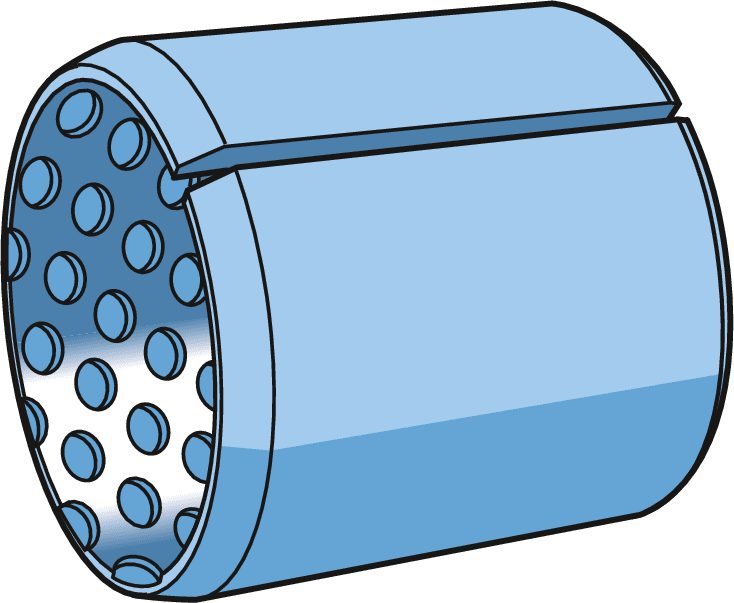

SKF sintered bronze bushings (table 1) are self-lubricating and maintenance-free. These bushings have a porous bronze matrix impregnated with lubricant. The permissible sliding velocity for sintered bronze bushings is very high, making them suitable for rotating applications. SKF offers a wide range of both straight and flanged sintered bronze bushings (fig. 2). Advantages of these bushings include:

very high sliding velocity

lubrication-free

maintenance-free operation

good frictional properties

SKF sintered bronze bushings are most suitable for applications with rotating movements and where self-lubricating properties of the material are a prerequisite. Application area examples for these bushings are:

electrical equipment

household equipment

printing machinery

machine tools

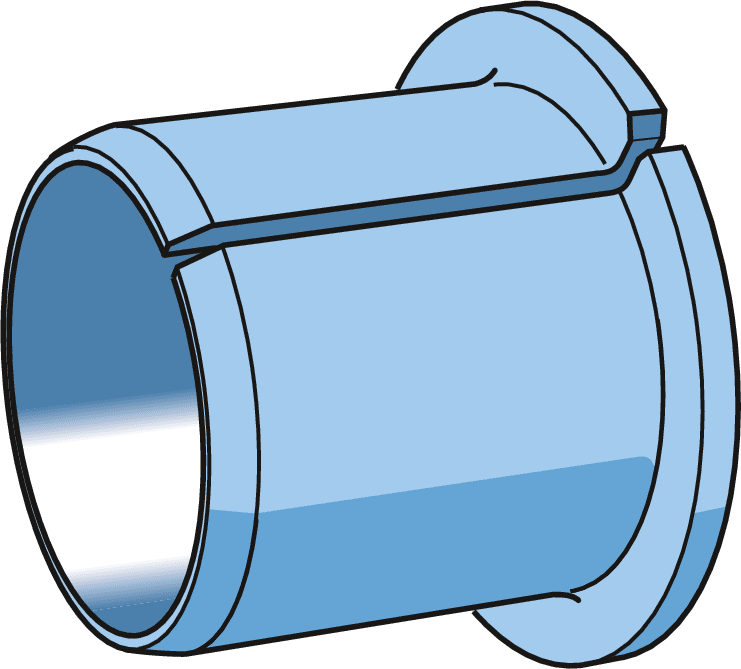

SKF wrapped bronze bushings (table 1) are particularly well suited for applications where high levels of contamination make relubrication necessary. The sliding surface of these bushings contains diamond shaped pockets that serve as reservoirs to progressively release lubricant during operation and, therefore, initially need to be filled with grease. SKF offers a wide range of both straight and flanged wrapped bronze bushings (fig. 3). Advantages of these bushings include:

insensitive to contaminated environments

resistant to shock loads and vibrations at slow speeds

good resistance to corrosive environments

SKF wrapped bronze bushings are well suited for machinery that operates in highly contaminated environments and where shock loads and/or vibrations occur. Application area examples for these bushings are:

agricultural machinery

hoisting equipment

construction machinery

forestry machinery

SKF PTFE composite bushings (table 2) are the maintenance-free solution for heavy load/medium speed applications. SKF offers a wide range of both straight (fig. 4) and flanged (fig. 5) PTFE composite bushings. Advantages of these bushings include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high operating temperatures

high sliding velocity

small operating clearance

SKF PTFE composite bushings are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these bushings are:

automotive

material handling equipment

home appliances and consumer goods

textile machinery

SKF POM composite bushings (table 2) are referred to as prelubricated because their material is designed to operate with marginal lubrication. These bushing type effectively fills the gap between fully lubricated and dry sliding bushings. SKF offers a wide range of straight POM composite bushings (fig. 6). Advantages of these bushings include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high sliding velocity

small operating clearance

SKF POM composite bushings are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these bushings are:

agricultural equipment

construction machinery

material handling equipment

home appliances and consumer goods

SKF PTFE polyamide bushings (table 3) provide maintenance-free, dry sliding operation and are designed for applications where other polymer bushings might fail prematurely. These thin-walled bushings promote heat dissipation, enabling high sliding velocities. SKF offers a standard assortment of both straight and flanged PTFE polyamide bushings (fig. 7). Advantages of these bushings include:

maintenance-free operation

cost-effective

corrosion-resistant

electrical insulator

SKF PTFE polyamide bushings are suitable for applications where cost-effective maintenance-free bushings are preferred. Application area examples for these bushings are:

textile machinery

medical equipment

fitness equipment

household equipment

SKF filament wound bushings (table 4) are made of resin and fibres wound in multiple layers. Modern filament winding technology has made it possible to produce a new, innovative bearing material. It combines the special mechanical properties of glass fibre with the excellent tribological properties of high-strength thermoplastic and PTFE fibres embedded in epoxy resin. The defined position of the strands in the criss-cross pattern and the intensive binding between the strands and the resin provide enables this composite material to accommodate heavy loads and vibrations in corrosive environments. SKF filament wound bushings are often dimensionally interchangeable with solid bronze or steel bushings. SKF offers a standard assortment of straight filament wound bushings (fig. 8). Advantages of these bushings include:

high load carrying capacity

ability to accommodate shock loads and vibrations

good impact resistance

insensitive to misalignment and edge loading

good noise and vibration damping

maintenance-free operation

corrosion-resistant

very good chemical resistance

very good frictional behaviour

very good electrical insulator

SKF filament wound bushings are suitable for applications where heavy loads together with vibrations occur and where maintenance-free operation is preferred. Application area examples for these bushings are:

construction machinery

agricultural and forestry machinery

hoisting and conveyor equipment

offshore equipment

SKF PTFE composite thrust washers (table 5) are suitable for space-saving axial locating bearing arrangements for heavy load/medium speed applications. SKF offers a wide range of PTFE composite thrust washers (fig. 9). Advantages of these bushings include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high operating temperatures

high sliding velocity

SKF PTFE composite thrust washers are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these washers are:

automotive

material handling equipment

home appliances and consumer goods

textile machinery

SKF POM composite thrust washers (table 5) are suitable for space-saving axial locating bearing arrangements. They are referred to as prelubricated because their material is designed to operate with marginal lubrication. SKF offers a wide range of POM composite thrust washers (fig. 10). Advantages of these washers include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high sliding velocity

SKF POM composite thrust washers are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these bushings are:

agricultural equipment

construction machinery

material handling equipment

home appliances and consumer goods

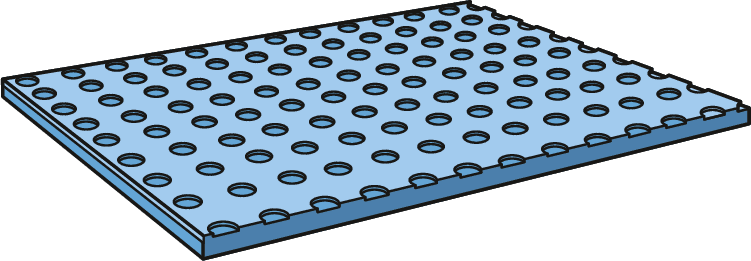

SKF PTFE composite strips (table 6) are suitable for space-saving arrangements of all types. These stripes can easily be fit to the application and counterface. SKF offers a wide range of PTFE composite strips (fig. 11). Advantages of these stripes include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high operating temperatures

high sliding velocity

SKF PTFE composite strips are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these strips are:

automotive

material handling equipment

home appliances and consumer goods

textile machinery

SKF POM composite strips (table 6) are suitable for space-saving arrangements of all types. These stripes can easily be fit to the application and counterface. They are referred to as prelubricated because their material is designed to operate with marginal lubrication. SKF offers a wide range of POM composite strips (fig. 12). Advantages of these strips include:

maintenance-free operation

very good frictional properties

high load carrying capacity

high sliding velocity

SKF POM composite strips are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these bushings are:

agricultural equipment

construction machinery

material handling equipment

home appliances and consumer goods