Technology and key benefits

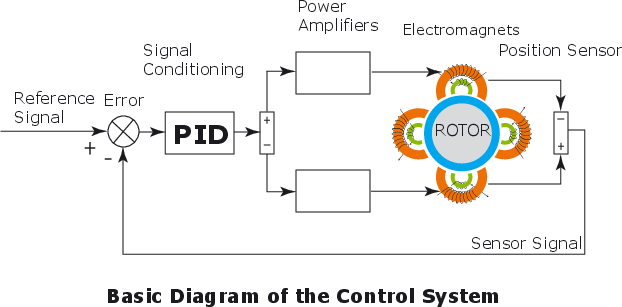

Active magnetic bearings operate with no surface contact eliminating bearing friction and wear. Electromagnets generate forces in radial and axial directions to levitate the shaft, allowing it to rotate contact-free. A control system actively monitors and continuously adjusts the current in the electromagnets to maintain shaft position. Their extreme precision and stability makes them suitable for a much wider operating range than conventional bearings.

higher reliability and energy efficiency

virtually maintenance-free, reduced cost of operation

oil-free and contamination-free

high damping properties, withstand high transient loads

allow active control of the shaft unbalance

instantaneous and unlimited start/stop

operate in vacuum and in process gas, enabling sealed machines design

built in monitoring system

Magnetic bearings – Principles of operation

–>